Products

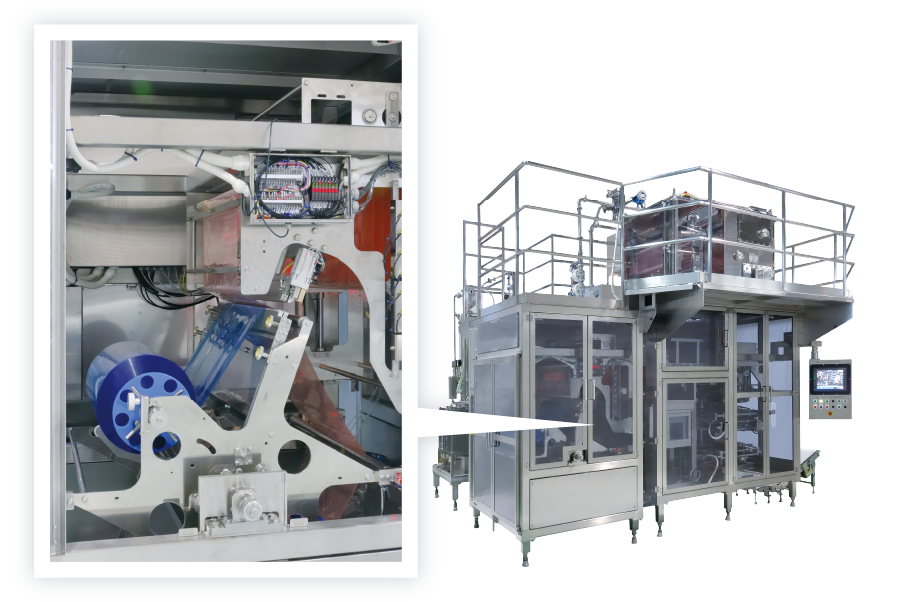

About Packaging Machines

Onpack Theme

we will provide more value-added and creative packaging systems.

- Streamlining

of Distribution - Production

EfficiencyFood SafetyThe Onpack brand has had more than 50 years of experience and achievements in food industry all over the world, and continues to evolve as a brand with originality and novelty. Orihiro has been working on the development of vertical form-fill-seal machine that uses flexible packaging materials to fill various fluids and solids.

Today, we have incorporated a new, advanced filling and packaging technology, including the aseptic filling packaging system that can respond to diverse needs of customers. We will continue trying to understand the needs customer in the market and to work on the challenges to technological innovation.

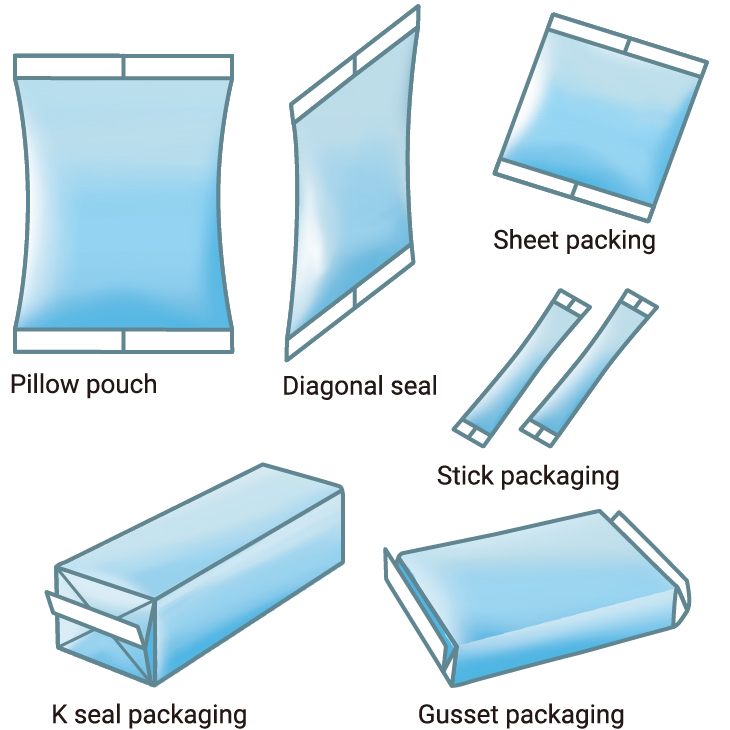

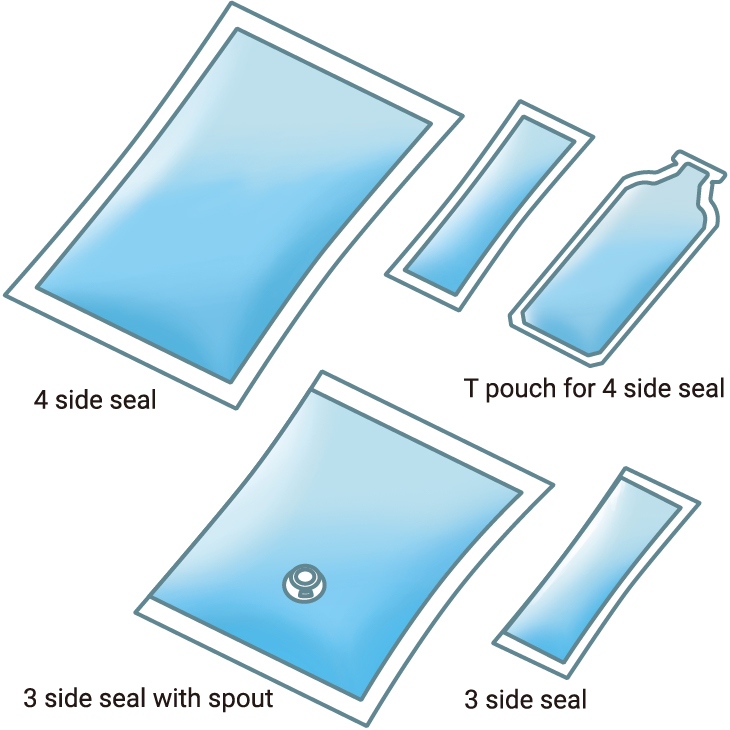

Onpack Package Format

Flexible package

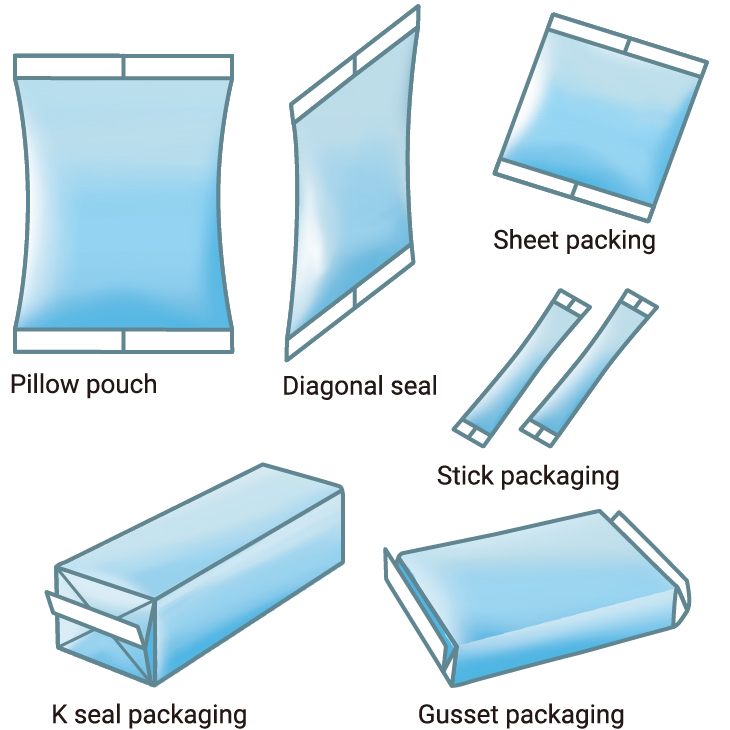

Pillow pouch packaging

Pillow pouch packaging is a basic packaging format that represents Onpack packaging equipment, that has been highly

acknowledged by customer all over the world. This packaging has been used as a delivery container from the central factory to the restaurant chains and fast food chains.

The advantage of this packaging format is to be able to maximize the product loading per unit area of the film.

With this packaging format, it is easy to avoid the issues that could happen during the production process, such as the wrinkles issue that is critical for food packaging. Also high viscosity product can be filled under high temperature.

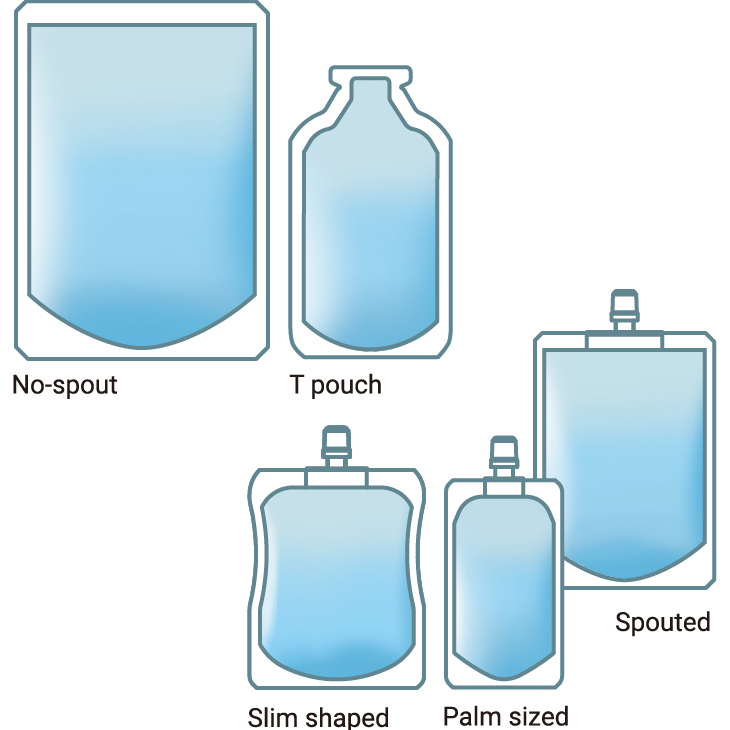

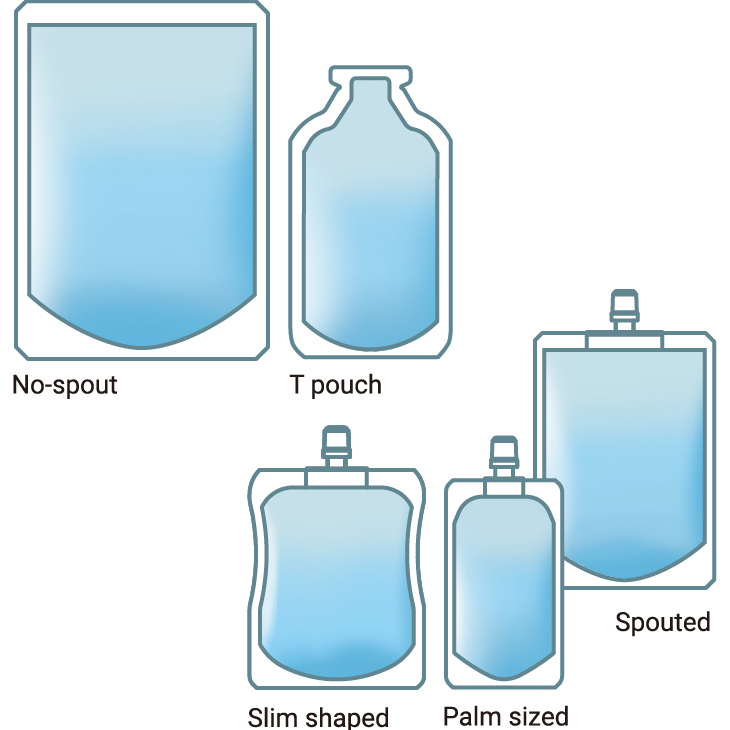

Stand up pouch packaging

This is popular packaging design due to its convenient and the ease of use with reclose-able function. In-line spout application and the roll film feeding method unique in Onpack packaging systems can significantly reduce the operational cost of packaging materials compared to conventional premade bag filling-packaging methods.

Packaging design can be customized in various ways, including the shape and size of the pouch, the shape of the corner cut, shape of the spout and the additional holes.

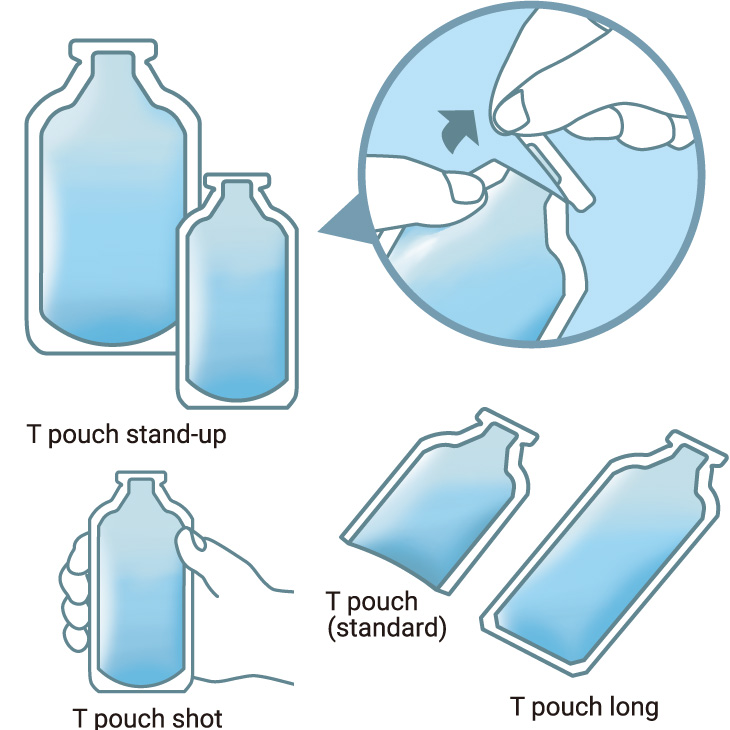

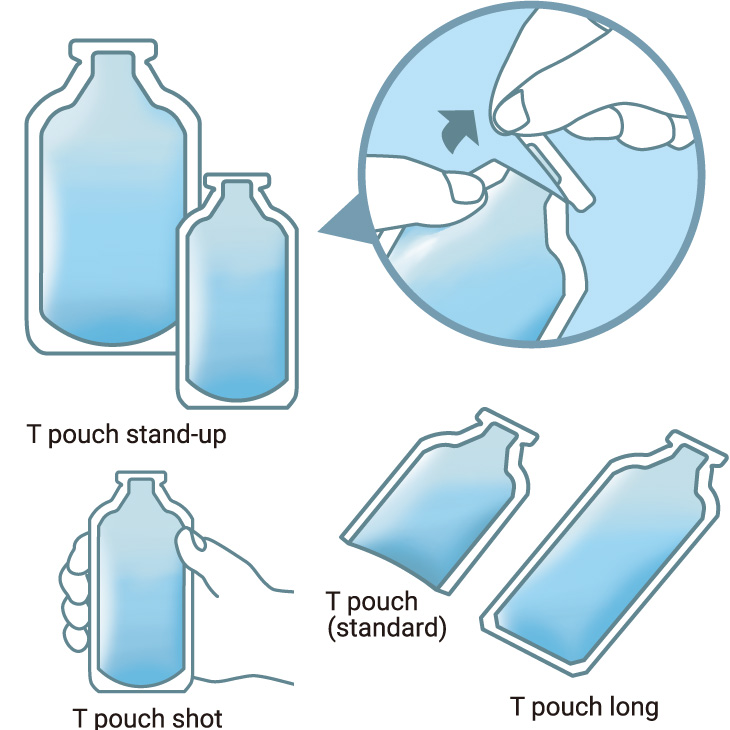

T pouch packaging

Olihiro's proprietary packaging format has attracted attention for its originality in design, ease of use for users, and cost benefits. The top parts can be torn straight, easy to open, there is no worry about dripping when opening. There is no need for additional spout/fitment.

It is environmentally friendly, reduces the amount of plastic resin, and can significantly reduce the material costs compared to with the spout.

"T pouch shot" fused with small volume standing pouch.We will keep developing new packaging forms that meet customer

needs one after another.

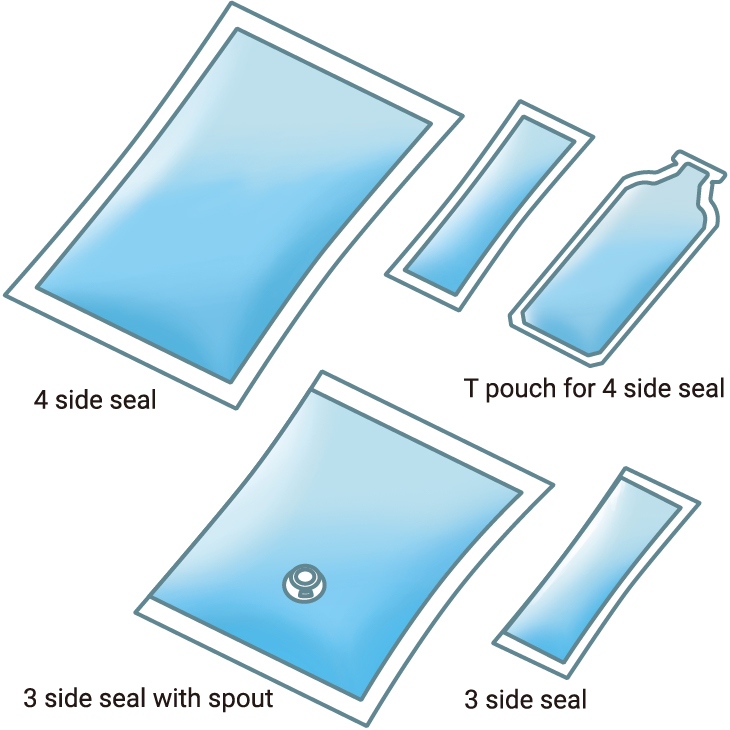

3 side / 4 side seal packaging

This is the popular format of packaging.

In-line spout application and the roll film feeding significantly can reduce the operational cost of packaging materials compared to conventional bag-pre-made methods.

It is flexible and can be customized in various ways, including the shape and size of the pouch, the shape of the design cut, and the shape of the spout.

Pillow pouch packaging

Pillow pouch packaging is a basic packaging format that represents Onpack packaging equipment, that has been highly

acknowledged by customer all over the world. This packaging has been used as a delivery container from the central factory to the restaurant chains and fast food chains.

The advantage of this packaging format is to be able to maximize the product loading per unit area of the film.

With this packaging format, it is easy to avoid the issues that could happen during the production process, such as the wrinkles issue that is critical for food packaging. Also high viscosity product can be filled under high temperature.

Stand up pouch packaging

This is popular packaging design due to its convenient and the ease of use with reclose-able function. In-line spout application and the roll film feeding method unique in Onpack packaging systems can significantly reduce the operational cost of packaging materials compared to conventional premade bag filling-packaging methods.

Packaging design can be customized in various ways, including the shape and size of the pouch, the shape of the corner cut, shape of the spout and the additional holes.

T pouch packaging

Olihiro's proprietary packaging format has attracted attention for its originality in design, ease of use for users, and cost benefits. The top parts can be torn straight, easy to open, there is no worry about dripping when opening. There is no need for additional spout/fitment.

It is environmentally friendly, reduces the amount of plastic resin, and can significantly reduce the material costs compared to with the spout.

"T pouch shot" fused with small volume standing pouch.We will keep developing new packaging forms that meet customer

needs one after another.

3 side / 4 side seal packaging

This is the popular format of packaging.

In-line spout application and the roll film feeding significantly can reduce the operational cost of packaging materials compared to conventional bag-pre-made methods.

It is flexible and can be customized in various ways, including the shape and size of the pouch, the shape of the design cut, and the shape of the spout.

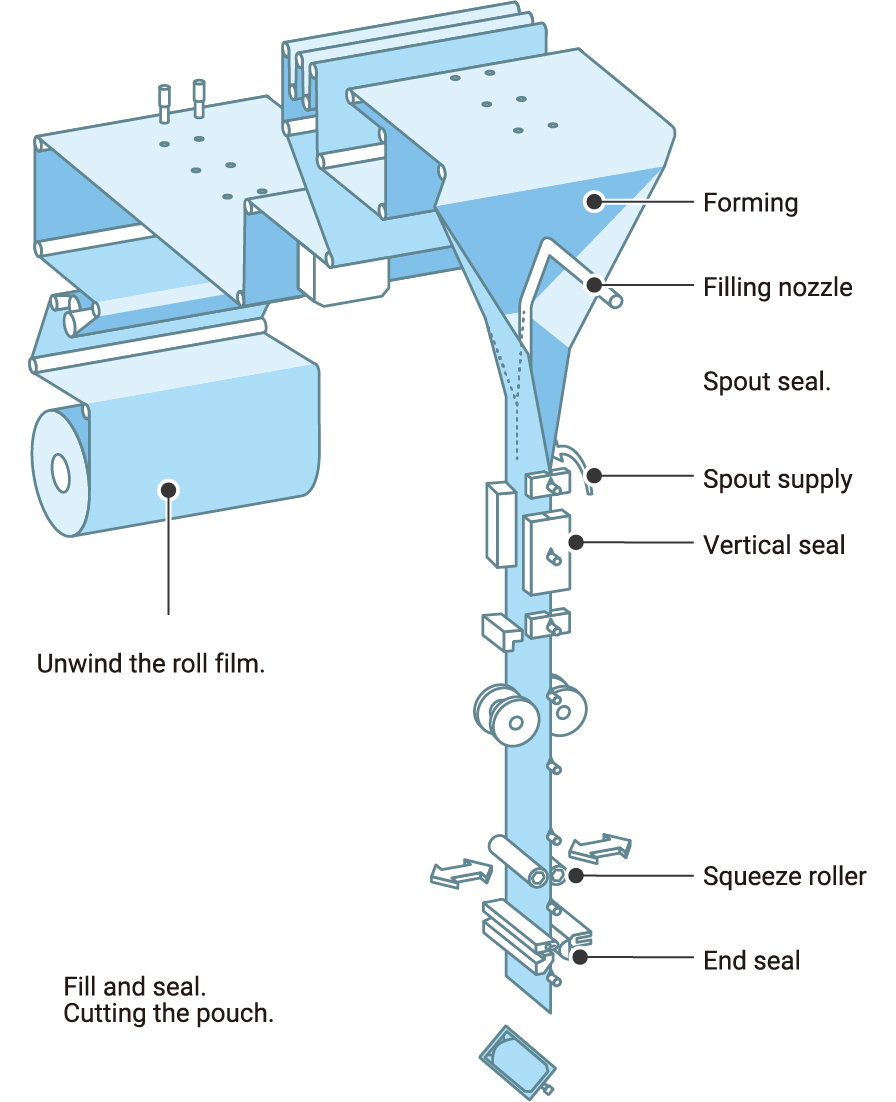

Onpack's Unique Packaging Technology

Onpack's unique packaging technology with many outstanding features.

Significantly lower packaging costs

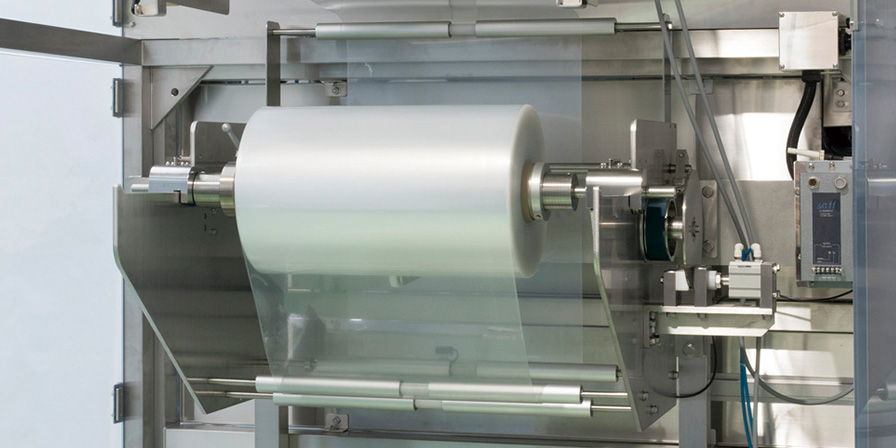

A method of roll film feeding out and forming in line. Packaging costs can be significantly reduced compared to using pre-made bag operation.

All-in-one method

“All-in-one method” makes consistent processing method from spout supply to bag making, filling, sealing and corner trimming in-line. Which significantly reduce the size of equipment, simplify the filing operation and reduce the operational cost.

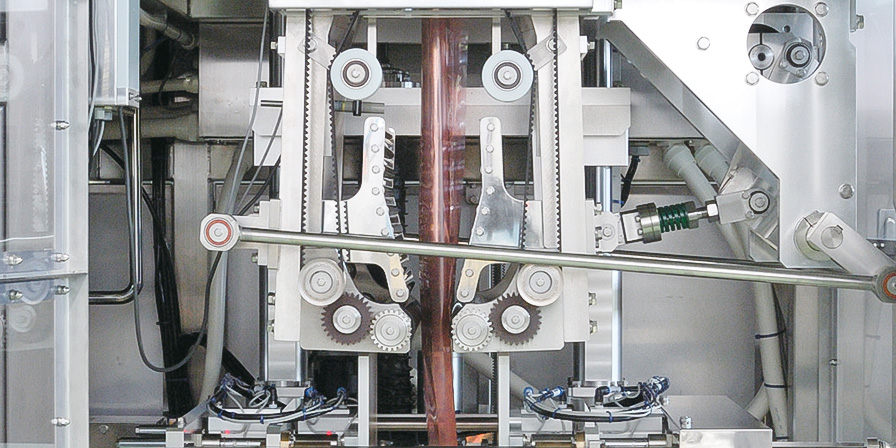

Onpack unique seal method

Unique "Scatt seal" method that can cool and solidify the seal immediately after heat sealing that improves the hot tack and prevent the tunnel leakage happen in the cross-section with the vertical seal. With "push-out " seal method, it is possible to seal through the product. Recently, we completed the ultrasonic sealing method and dramatically improved the seal quality for the aluminum foil materials and for the retort packaging materials. The Onpack sealing method has a wide range suitability with the product filling temperature, allowing hot fill with very high temperature of the product.

Squeeze roller

There is the roller mechanism that can removes the product from the target seal area. With this mechanism, filling and packaging the edible oils, fats, high viscosity glazes, detergents, etc, which are considered difficult in sealing. In addition, the head space (air in pouch) in the bag can be eliminated with squeeze roller, which prevent the product damage due to burn and oxidation when further heat process is required such as boiling and retort.

Easy to resize

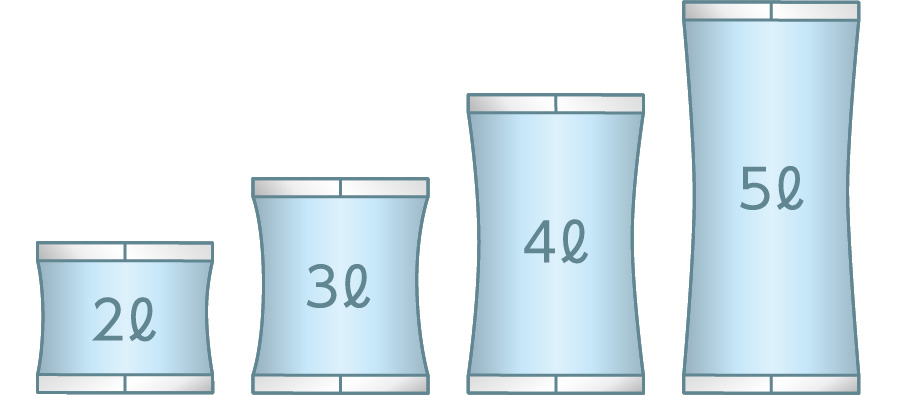

Because of the direct film supply system from roll stock, the packaging size can be easily changed depending on the volume of product. Quick setup and changeover is possible (Only when the pillow pouch). The use of no printed film may reduce the inventory of roll stock material and ease the inventory control.

【Optional item】

Automatic film splicer

There is no need to stop the production while roll film is changed.

The automatic film splicer can minimize the production downtime and helps increase production efficiency.