ORIHIRO Material Co., Ltd.

About ORIHIRO Material

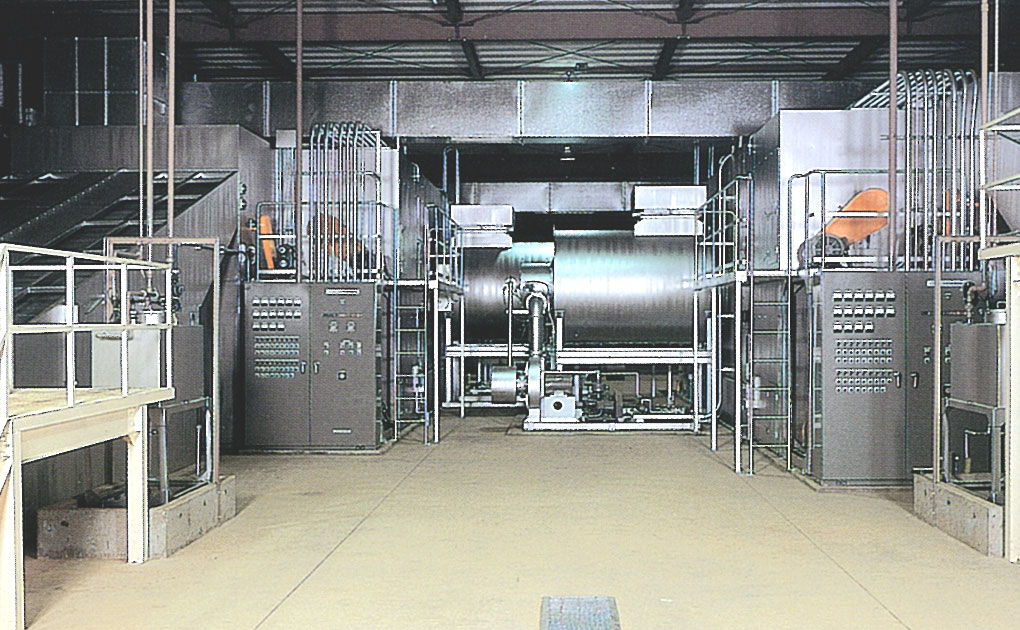

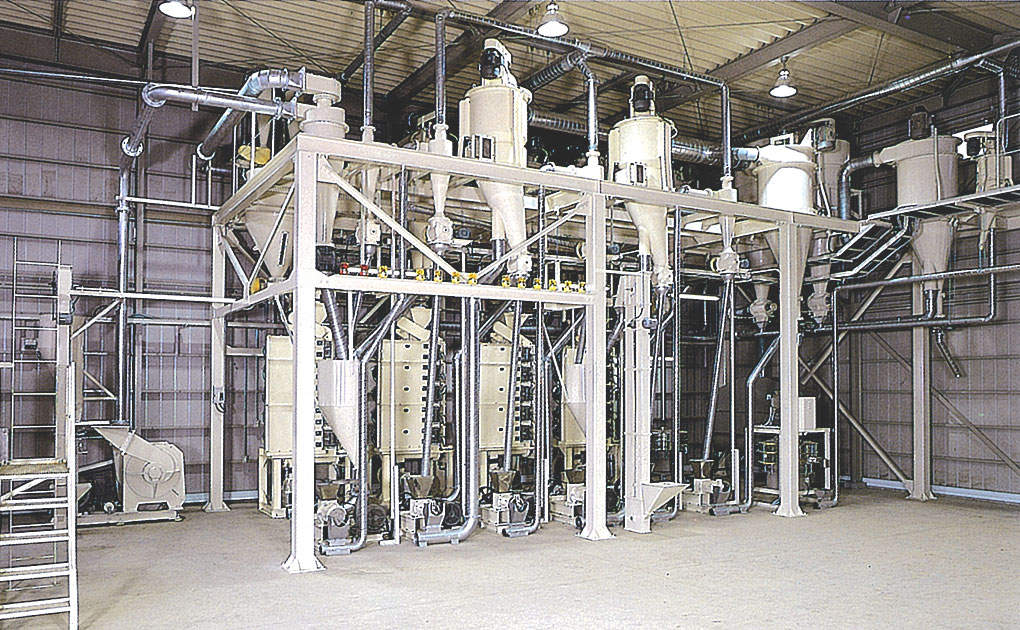

We have built our own production line and an integrated system that makes the best use of our know-how in each process, which is the key point from drying konjac raw potatoes to fine powder, compounding, quality inspection, and storage. We provide a stable supply of high-quality, high-purity mannan, which is indispensable for producing high-quality konjac products.

Business content

Konjac raw materials business / Manufacturing and sales of konjac raw material

Manufacture of konjac raw materials

Processing

Primary processing

In the primary processing, locally cultivated konjac potatoes are sorted by type or size and then washed. Then slice it to a thickness of about 2 to 3 mm and go to heat dryer to make dried "rough powder".

Second processing

In the secondary processing, refinement processing is performed to extract glucomannan from dried rough powder. Next, pressure is applied to the rough powder to crush it, and polishing is repeated to remove impurities. Then, the viscosity of the extracted mannan is inspected to make the optimum blending. Products are inspected again, and those that do not meet the quality standard are reprocessed again.

From storage to shipping

Good quality products are stored in a cold warehouse so that the viscosity of Mannan is not compromised and shipped when an order is placed.

Factory / quality inspection

Development of konjac products

Orihiro Material have developed "Timac Mannan", which cuts the odor peculiar to konjac, and "AF Mannan" which is dissolved in water and aseptically packaged in a gel form. A number of new initiatives are continuously underway, such as the development of foods with new texture, foods with functional claims using glucomannan, and foods for specified health uses.